Couldn't load pickup availability

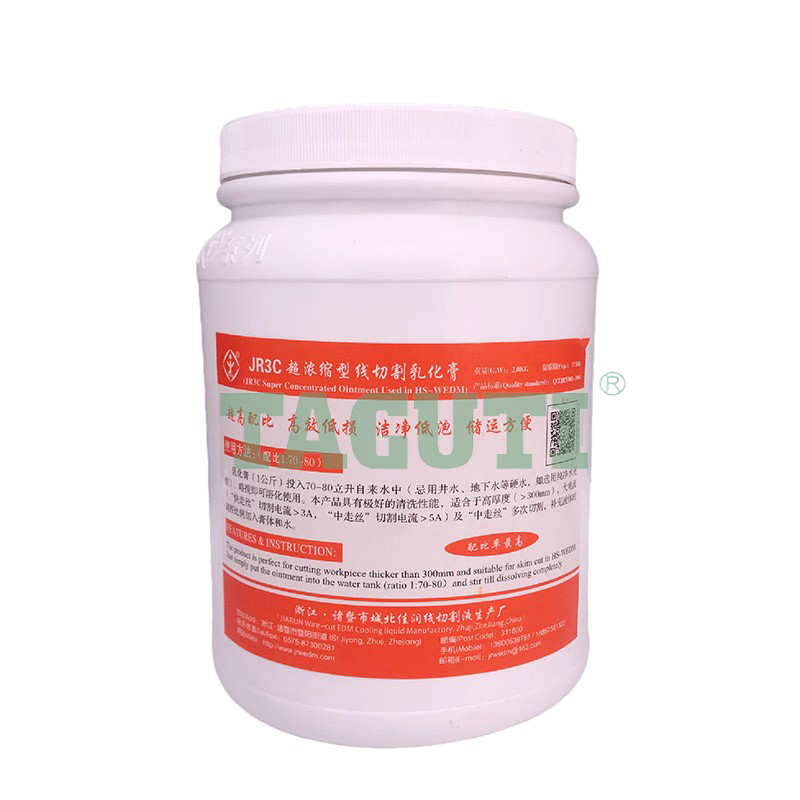

JR-3C Ointment Gel for HS-WEDM (Super Concentration) or JR-3C EDM gel has high concentration, environmental friendly character, fast processing speed, good finish and good chip removal, suitable for processing large thickness workpieces.

- Put the ointment into running water with a ratio 1:70-80 and stir until mix the ointment into water thoroughly;

- Avoid hard water such as well water or ground water.

1. The productJR-3C is currently the highest concentration of working liquid;

2. Uniform and whitefinish surface without commutation stripes after the workpiece is cleaned with kerosene;

3. Under high-energy processing conditions (average processing current>5A), it has good cutting stability. Compared with traditional emulsified oil, JR-3C’scutting efficiency is increased by 30%, the surface quality is improved by half, the electrode wire loss is reduced by 50%, and the service life of molybdenum wire greatly extended;

4. There is basically no foam during processing, and workbench surfaceis clean;

5. Suitable for cutting within 500mm thickness die steel.

Specially suitable for multiple-cut of WEDM-HS.

1. When replenishing, please add JR-3Cand water in proportion;

2. Please use themagnet to suck the workpiece after cutting, so as not to drop and break the molybdenum wire;

3. When cutting large thickness, properly slow down the variable frequency tracking speed, adjusting from zero to stable cutting, and the ammeter will basically no longer shake.

Receive our latest updates about our products and promotions.

Thanks for subscribing!

This email has been registered!