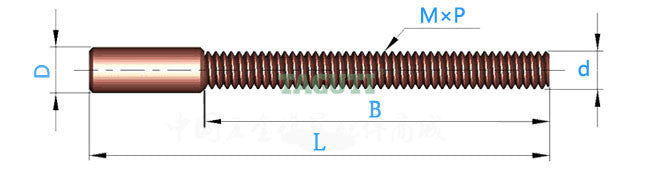

Thread Electrode Tapping Electrode Without Hole

1.The applications of thread electrode: tapping electrodes of electrical discharge Machining (EDM) play an important role in mould processing as EDM tapping engages the discharge...

Description

1.The applications of thread electrode: tapping electrodes of electrical discharge Machining (EDM) play an important role in mould processing as EDM tapping engages the discharge process of mould cavity. The manufacture level and EDM technology of thread tapping electrode are vital for the quality of tapping electrode and standard of processing directly impact the quality of product itself.

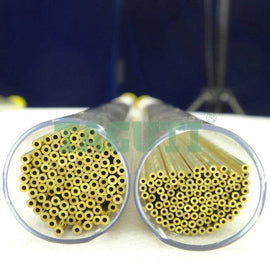

2.Materials of thread electrode: high-quality copper, tungsten copper, beryllium copper, etc.

3.Features of TAGUTI threading electrodes: high purity, good electrical and thermal conductivities, strong anti-oxidation, fine corrosion resistance and excellent processability.

※Special specifications of thread electrode can be customized!

※Special specifications of thread electrode can be customized!